Lobed Impeller Flowmeter: Advantages and Disadvantages

Advertisement

This article explores the pros and cons of using a lobed impeller flowmeter. We’ll cover its working principle, benefits, and limitations to help you understand if it’s the right choice for your flow measurement needs.

What is a Lobed Impeller Flowmeter?

A lobed impeller flowmeter is a type of positive displacement meter. It works by directly measuring the volume of fluid or gas that passes through it. Here’s how it functions:

-

Dual Impellers: The core of the meter consists of two specially shaped, lobed impellers. These impellers are geared together and rotate in opposite directions within a housing. Think of it as two gears meshing together, but with a specific shape to capture fluid.

-

Positive Displacement: As the fluid flows through the meter, it pushes against the impellers, causing them to rotate. Each rotation displaces a precise, known volume of the fluid.

-

Flow Measurement: The number of rotations is directly proportional to the total volume of fluid that has passed through the meter. This is how the flow rate is measured.

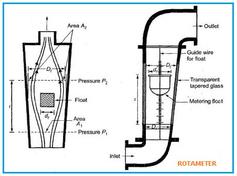

- Figure 1: A simplified representation of a Lobed Impeller Flowmeter.

Key Points:

- Lobed impeller flowmeters belong to the family of positive displacement meters, which also includes nutating disk, oscillating piston, rotating vane, oval gear, and reciprocating piston types.

- Unlike some other flowmeters, lobed impeller flowmeters directly measure volume rather than inferring it from other parameters.

Advantages of Lobed Impeller Flowmeters

Here are the key benefits of using a lobed impeller flowmeter:

- High Accuracy: They offer exceptional accuracy in gas measurement, typically ranging from +/- 0.1% to +/- 0.5%. This makes them suitable for applications that demand precise readings.

- No Straight Runs Required: Unlike some other flowmeters, lobed impeller types do not need specific inlet or outlet sections, simplifying installation.

- Self-Powered: They don’t need an external power source to operate, making them ideal for remote or power-limited locations.

- High Pressure Operation: These meters can operate effectively at high pressures, up to 8 MPa.

- High Temperature Operation: They can withstand high temperatures, functioning reliably up to 200°C.

Disadvantages of Lobed Impeller Flowmeters

While they offer many advantages, it’s crucial to be aware of the drawbacks:

- Gas Only: These flowmeters are primarily designed for measuring gas flow; they are not typically suitable for liquids.

- Moving Parts: The internal moving parts are subject to wear and tear over time, potentially impacting accuracy and requiring maintenance.

- Susceptible to Blockage: Solid impurities in the flow can obstruct the impellers, leading to inaccurate readings or even complete blockage at zero flow.

- Contamination Issues: They are susceptible to contamination, which can increase pressure drop and necessitate regular cleaning.

- Impact of Pressure Fluctuations: Rapid changes at high differential pressures can affect measurement accuracy.

- Difficult Monitoring: Monitoring performance can be a complex task due to the mechanical nature of the system.

- Poor Low Flow Accuracy: They exhibit poor accuracy at very low flow rates.

- Bulky and Heavy: These meters tend to be larger and heavier than some other types of flowmeters.

- High Cost: They can be more expensive compared to some other flow measurement solutions.

Conclusion

Lobed impeller flowmeters are a reliable option for gas measurement where accuracy and self-powered operation are essential. However, their limitations, such as suitability for gases only, potential for wear, and susceptibility to contamination, must be considered. Carefully evaluating the specific requirements of your application will help you determine if a lobed impeller flowmeter is the right choice.

Advertisement

T&M

T&M