Flow Meter vs. Flow Switch: Key Differences Explained

Advertisement

When it comes to managing the movement of fluids, whether liquids or gases, two common devices come into play: flow meters and flow switches. While both are related to flow, they serve distinct purposes. Let’s break down the differences between these important components.

What is a Flow Meter?

A flow meter is essentially a measurement tool. Its primary job is to determine the rate or quantity of fluid flowing through a pipe or channel. Think of it like a speedometer for fluids. It tells you how much fluid is moving and how fast it’s going.

Flow meters are used in a variety of applications, from monitoring water usage in homes to tracking the flow of chemicals in industrial processes. They provide valuable data that helps us understand and manage fluid systems.

Examples of Flow Meters

- Differential Pressure Flow Meters: These use pressure differences to calculate flow, including devices like:

- Orifice plates

- Venturi meters

- Flow nozzles

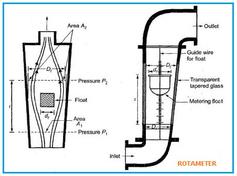

- Rotameters

- Positive Displacement Flow Meters: These measure flow by trapping and releasing known volumes of fluid, such as:

- Piston flow meters

- Gear flow meters

- Helical flow meters

- Open Channel Flow Meters: Used for measuring flow in channels with open surfaces, like:

- Flumes

- Weirs

- Sluice gates

- Electromagnetic Flow Meters: These use magnetic fields to measure flow, particularly useful for conductive fluids.

What is a Flow Switch?

A flow switch, on the other hand, is a control device. Its main function is to monitor whether fluid flow is present and to trigger an action based on that presence or absence. It’s less about precise measurement and more about detecting a condition – is the fluid flowing or not?

Flow switches are often used as safety mechanisms, protecting systems from damage by ensuring that fluid flow is present when needed.

How Flow Switches Work

Flow switches typically send signals to other devices, often pumps. If flow stops (or reduces below a set point), the flow switch can:

- Turn off pumps to prevent them from running dry or overheating.

- Turn on pumps to re-establish flow, if required.

- Activate alarms or relays to alert operators to the flow condition.

Examples of Flow Switches

- Water Flow Switches: Frequently used in water sprinkler systems to ensure that water is flowing when the system is activated.

- Air Flow Switches: Commonly found in air handling systems, like:

- Room filter systems

- Air treatment systems

- Exhaust ventilation systems

Key Differences Summarized

To make it clearer, here’s a quick comparison:

| Feature | Flow Meter | Flow Switch |

|---|---|---|

| Primary Role | Measures the rate or quantity of flow. | Detects the presence or absence of flow. |

| Output | Provides data on flow rates or volumes. | Sends a signal based on flow presence/absence. |

| Usage | Monitoring, data logging, process control. | System protection, alarm activation, control of other devices. |

| Precision | Designed for accurate flow measurement. | Designed for reliable flow detection. |

In Simple Terms

Think of it like this:

- A flow meter is like a car’s speedometer – it tells you how fast you’re going and how far you’ve traveled.

- A flow switch is like the low oil pressure light in your car – it alerts you when a critical condition (low or no flow) is detected.

Both flow meters and flow switches are important tools, each fulfilling a critical role in ensuring the safe and efficient operation of fluid systems. Understanding their differences helps in selecting the right device for a specific application.

T&M

T&M